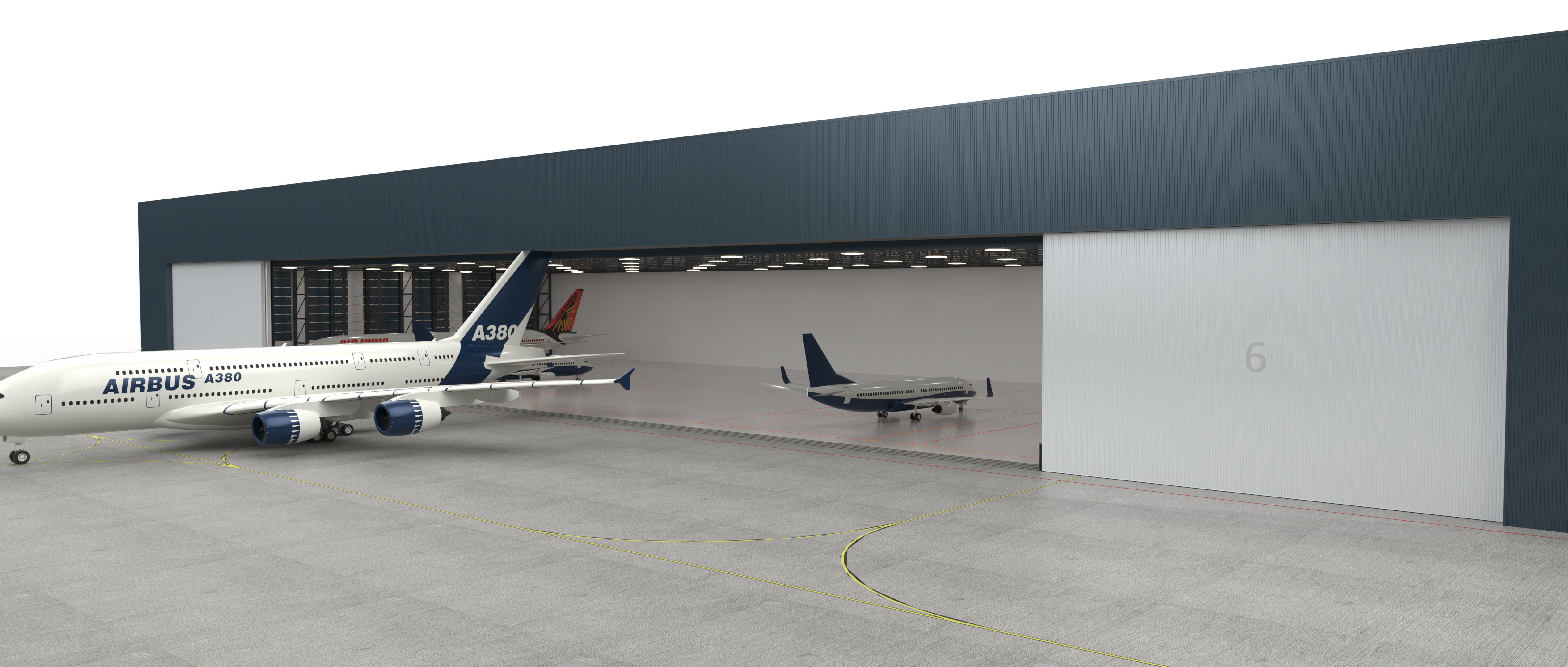

HowBigIsBig- for us at Jugapro Butzbach, 27 meters in height and 206m in width

The work processes in an aircraft hangar are demanding, requiring the highest level of organization, efficiency, and reliability from both people and technology. As a manufacturer of hangar doors that is in demand worldwide, Jugapro strives to create the best working conditions in aircraft hangars and at airports with its products. We provide full support from the initial stages, assisting with all planning considerations. Our experts offer advice on determining the size and position of your hangar door, as well as guidance on the opening principle, type of drive, and choice of filling material. We take into account all relevant safety devices and accommodate your architectural and design requirements. Our team of competent partners is personally available to answer any questions regarding the conception and planning of your hangar door.

Aircraft Hangar Doors: More Than Just Sliding Doors

While they may appear as just another set of sliding doors, aircraft hangar doors are meticulously engineered for aviation needs. These doors are designed to:

Provide Large Clear Openings: Essential for the smooth ingress and egress of aircraft.

Ensure Durability: Built to withstand extreme weather conditions and frequent usage.

Guarantee Reliability: Engineered for consistent performance to ensure safety and operational efficiency.

Another Successful Project: MRO Hangar Doors Delivered in Record Time

At Jugapro we thrive on tackling new challenges and delivering exceptional results. Our latest accomplishment at a major airport highlights our expertise and efficiency in providing top-tier hangar door solutions.

Challenge Accepted: Faced with unique requirements and tight deadlines, our team rose to the occasion.

Massive Scale: The MRO hangar was designed to accommodate some of the largest aircraft, requiring robust and reliable door solutions.

Rapid Delivery: Despite the complexities, we delivered and commissioned the hangar doors in record time, showcasing our efficiency and commitment to excellence.

Types of Door Opening

Sliding gate principle

Sliding gates have freely movable gate leaves, so that each gate element can be moved individually on the rails. So you can always open and close your hangar exactly where it is needed.

Telescopic sliding gate principle

With the telescopic sliding gate, the gate elements are coupled with one another and are opened and closed again at the touch of a button. This makes operation easier for you and gives you quick access to the hangar.

Principle of revolving door

With our rotary door, each door element is optionally guided along the side wall of the hangar on the inside or outside – a great advantage if your space is limited or you have special hangar shapes such as round halls.

Sliding gate principle

Sliding gates have freely movable gate leaves, so that each gate element can be moved individually on the rails. So you can always open and close your hangar exactly where it is needed.

Telescopic sliding gate

With the telescopic sliding gate, the gate elements are coupled with one another and are opened and closed again at the touch of a button. This makes operation easier for you and gives you quick access to the hangar.

Round of the corner

With our rotary door, each door element is optionally guided along the side wall of the hangar on the inside or outside - a great advantage if your space is limited or you have special hangar shapes such as round halls.

Media

Your benefits

Individual project management through a reliable specialist/expert

Huge design variety for all details on your hangar doors

High economic efficiency and reliablility

Consultancy, planning and manufacturing, as well as professional installation, by our trained staff

Global customer service straight from the manufacturer with fast response times

Many years of experience and over 850 references worldwide

HANGAR DOORS Suitable for every application

The bottom rails are connected to a drainage and cleaning system. If requested by the customer, a rail heating can also be integrated.

Due to roof deformations above the gate system, tolerance clearances (truss movement) must be created for compensation. In the case of sliding gate systems that stand on the ground, the truss movement (specification of the static calculation) above the gate system is taken into account.

Closing edge safety devices” have the task of ensuring personal safety on the narrow side/front of a gate leaf. The movement of the gate leaves creates non-visible spaces in the direction of travel, which pose a danger to people or objects. Touching the “closing edge safety device” triggers a stop command that stops the gate leaf and initiates a reverse movement (reversing).

The incorporation of vertical tail gates as lifting gates into the structural replacement of the gate truss leads to a reduction in the main gate height and hence cost reductions. For the rudder door, we use fiberglass that we produce ourselves and create a uniform look for your hangar door.

Gate drives are used to move gate leaves with heavy weights. Electric geared motors with a chain connection to the drive wheel are mostly used. The gate leaf is set in motion via a travel button and the necessary electrical control.

Fiberglass is a particularly versatile material and ideally suited for hangar doors. The fiberglass is particularly characterized by its light transmission, durability, thermal insulation and stability. More information about fiberglass development & production can be found here .

The Butzbach swing brake effectively limits the gate leaf speed (for manually operated gate leaves) in order to avoid the risk of accidents and damage. The normal sliding of a gate leaf is unchecked. Only when the set speed is exceeded does the gate leaf slow down via a pendulum detent, without electrical influence.

Walk-through doors allow people to quickly enter and exit without having to open the hangar door. We also offer designs that meet the requirements for barrier-free construction or emergency exit doors. Coordination with the building management system and in a variety of designs is possible.